|

Why does a

Prodigy instrument play like a much more expensive model?

|

| |

| |

|

|

The

people

|

| |

|

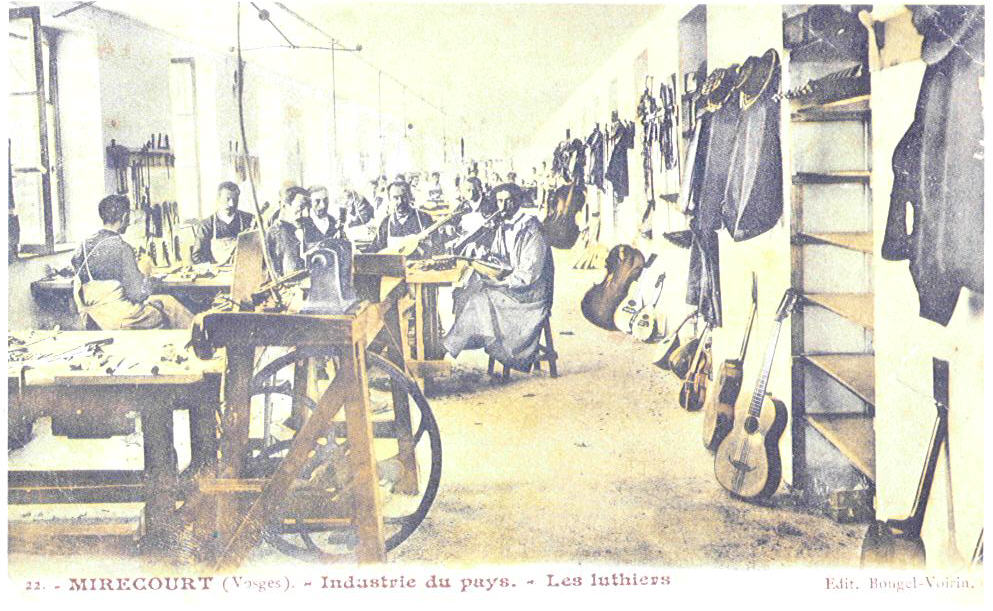

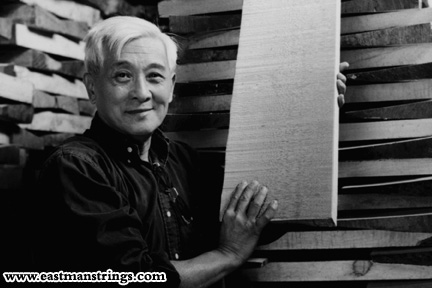

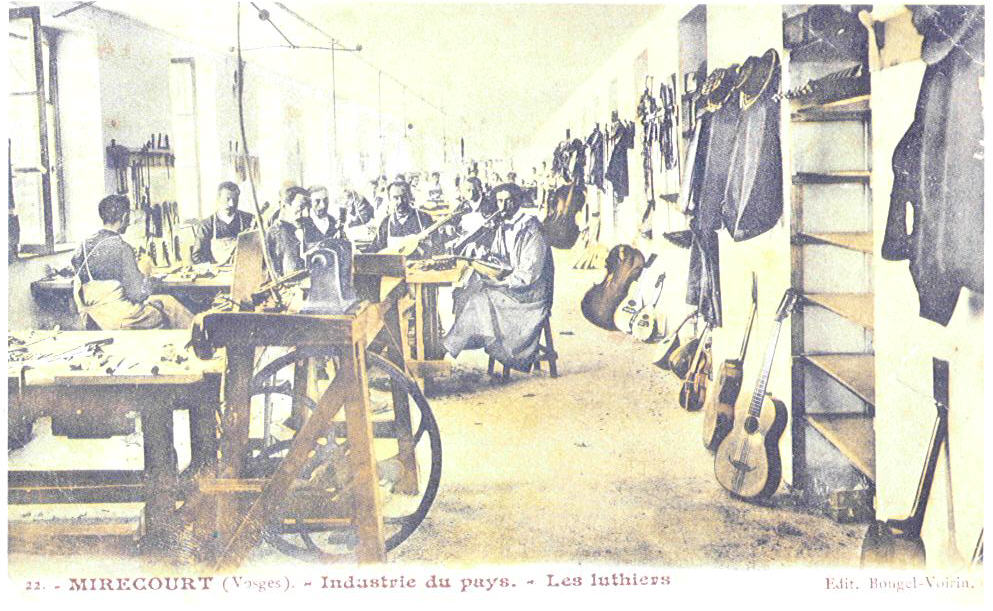

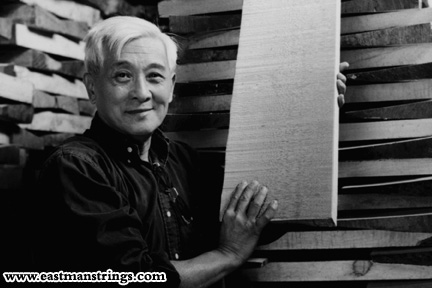

The master craftspeople who oversee every

step of the process are called Luthiers. The word “Lute” is

the root of this term. It refers to the maker of any string

instrument, whether bowed or plucked. Our Luthiers have made

building quality string instruments their vocation, travelling

to Europe to study with the masters. Only then do they return

to their home country and hand-craft string instruments for

Prodigy.

|

| |

|

Exceptional performance is built into every step

of the process

|

| |

|

1. The wood is hand

selected - aged spruce for the tops and maple for the backs,

ribs, necks, and scrolls.

The wood that is

chosen for the structure of the instrument will have a

great impact on the finished product. One can compare the

individual pieces of wood in a Prodigy instrument with the

ingredients that go into a gourmet meal. Even the most highly

skilled craftspeople in the world could not create a

masterpiece without the finest materials.

|

|

2. The

ribs are shaped in a rib mold.

Ribs must be thin but

strong. Their curvature imparts structural strength to

the body. But nonetheless, they are still the instrument’s

most delicate component.

|

|

3. Tops and backs are cut

from blocks of tonewood. Exterior arching is carefully shaped.

Depending on the model, tops and backs are cut from

either single pieces of tonewood, or from book-matched pairs

joined at the centre. The finely calibrated gradations in

thickness, called “graduations” are completed from the inside.

There is no machine that can perform this delicate work

with the accuracy of our luthiers. Correct graduations are

essential to how the instrument responds.

|

|

4.

F-Holes are cut in the tops.

F-Holes are rough cut

with a jeweller’s saw and then finished with a knife. These

holes are essential to the release of the instrument’s

sound. Experts can identify examples from historically

significant luthiers partly by the shape of their F-Holes.

|

|

5. The bass bar is glued to the inside of the top.

The bass bar is a slightly springy piece of wood that

provides support and enhances the bass notes of the

instrument. It is carved to match perfectly when glued

to the interior surface of the top. Then it is shaped for

strength and tonal enhancement.

|

|

6. The top, back and

ribs are glued together.

The edges of the top and back

are individually shaped to exactly follow the curvature of the

ribs.

|

|

7. Purfling.

The three layers of

purfling are protective as well as decorative. They are

meant to prevent any edge cracks from extending to the body of

the instrument. The carving of the purfling channels must be

precise to ensure there are no gaps between the thin wood of

the purfling and the edge of the channel where it is inlaid.

Prodigy luthiers take pride in their ability to cut and

inlay the purfling as precisely as possible.

|

|

8. The

scroll is carved from aged maple.

This hand made

sculpture is the basis of the instrument’s personality. No

two Prodigy scrolls are identical. So the scroll provides

the instrument’s signature. A neck carver takes over once the

scroll is complete, properly graduating the neck to make

playing easier.

|

|

9. The completed neck and scroll are

custom fitted to the neck block.

The proper angle

and a tight fit are essential to a Prodigy instrument’s

strength, sound and delightful playability. Edges and

corners now receive their final touches.

|

|

10. The

surface is scraped smooth.

A scraper is an unusually

shaped blade with a burred scraping edge, rather than a sharp

cutting edge. A scraped surface is superior to a sanded one

because it avoids the cloudy appearance of wood tat has been

sanded.

|

|

11. The instrument is varnished for beauty and

durability.

Brushes of different sizes are used so

that large surfaces and fine details can all be carefully

detailed. Necks are left unvarnished to provide a

smooth shifting surface. Prodigy uses modern fast drying

varnish to create a tough surface that resists scratches.

This varnish also allows the instrument to resonate better.

|

|

12. The instrument is carefully set-up to play

beautifully.

When the varnish is dry, the pegs and the

end button or endpin are fitted by hand using special tools.

Only top quality solid wood fittings are used. A custom

carved bridge and soundpost are fitted. Then the strings are

installed and the instrument is ready to play its first note.

The set-up of your Prodigy string instrument

is the final adjustment it receives before being

delivered. This includes how high the strings are from the

fingerboard, exact placement of the bridge and many other fine

details that make an instrument play well. There are

different ways to set-up an instrument. Musicians are very

particular about how their instruments are set-up. Prodigy

instruments are set up to MENC standards with a French bridge

and sacconi bridge arching. Since Prodigy instruments are

specifically intended for student musicians, every aspect

of the set-up is intended to help students play well from the

first note.

Prodigy carefully

chooses the wood and material

for our instruments to deliver an instrument with a look and

sound that is classic, rich, and smooth.

|

|

Attention to detail and proud craftsmanship create a

superior instrument

|

| |

Now that you

understand how a Prodigy instrument is created, you can see

why your Prodigy instrument will have more in common with a traditional

European instrument than the typical

machine-made European models of today.

Prodigy

instruments are designed to help musicians progress

faster. Since your instrument will be new, you can

depend on its reliability for

many years. See how your Prodigy

instrument compares to an older instrument

.

We invite you to delve further into our

story, and meet the people who are proud to

make Prodigy string instruments

.

|

|

|